Hay remains a cornerstone of livestock nutrition across America, with millions of tons harvested annually to sustain horses, cattle, sheep, and other farm animals through the changing seasons. Yet proper storage often receives less attention than it deserves, leading to significant financial losses and nutritional decline. Whether you’re a small hobby farmer with a few animals or managing a large agricultural operation, implementing effective hay storage practices ensures your feed remains fresh, nutritious, and free from harmful contaminants throughout the entire year. The following comprehensive guide explores proven methods for preserving hay quality from harvest to feeding, helping you maximize both your investment and the health of your animals.

Understanding Hay Quality Fundamentals

Before addressing storage practices, it’s essential to understand what constitutes quality hay and how it deteriorates over time. High-quality hay possesses optimal levels of protein, energy, and digestible nutrients while maintaining proper moisture content, typically between 15-18% for most varieties. The degradation process begins immediately after cutting, with exposure to oxygen, moisture, light, and microorganisms gradually reducing nutritional value and palatability. Each percentage point of protein lost represents real economic value disappearing from your feed inventory, with poorly stored hay potentially losing up to 50% of its nutritional content within just months. Recognizing these fundamentals helps emphasize why proper storage isn’t merely convenient but economically necessary for sustainable livestock operations.

Site Selection for Optimal Hay Storage

The location of your hay storage significantly impacts preservation quality, with ideal sites featuring key characteristics that protect your investment. Select elevated ground with natural drainage to prevent moisture wicking up from the soil, as even minimal ground contact can destroy the bottom layer of hay. Orientation matters too, with north-south alignments for outdoor stacks allowing maximum sun exposure to help dry morning dew that might accumulate. Consider wind patterns when positioning structures or stacks, as good airflow helps maintain appropriate moisture levels while preventing condensation buildup. Avoid areas beneath trees where debris and dripping moisture can contaminate hay, and ensure adequate distance from potential fire hazards according to local regulations and insurance requirements.

Indoor Storage Structure Options

Indoor storage provides the greatest protection against weather-related damage and typically results in minimal dry matter and nutrient losses. Purpose-built hay barns represent the gold standard, featuring proper ventilation, adequate height for equipment access, and overhanging roofs to prevent wind-driven precipitation from reaching the stack. Pole barns with open sides offer cost-effective alternatives that maintain airflow while providing crucial overhead protection. Hoop structures utilizing metal frameworks covered with UV-resistant tarps have gained popularity for their relatively low cost and ease of installation, though they typically have shorter lifespans than traditional buildings. Even repurposed structures like old dairy barns can function effectively when properly ventilated and protected from moisture intrusion through roof leaks or ground contact.

Outdoor Storage Techniques

When indoor storage isn’t available, strategic outdoor techniques can significantly minimize losses compared to unprotected exposure. Proper stacking patterns create a thatched-roof effect where water runs off rather than penetrating, with firmly packed stacks holding up better against wind damage. Elevating hay on pallets, railroad ties, or rock beds creates critical barriers against ground moisture that can wick upward into bales. Covering stacks with properly secured tarps extends protection, though ensure tarps don’t trap moisture by leaving sides open for ventilation when possible. Strategic stack orientation with the cut edges facing downward and away from prevailing weather patterns offers additional protection against moisture penetration. Well-implemented outdoor storage methods can keep deterioration to acceptable levels when indoor options aren’t feasible.

Moisture Management: The Critical Factor

Moisture represents the single greatest threat to stored hay, making its management paramount in preservation efforts. Harvest timing directly impacts initial moisture content, with ideal baling occurring when internal stem moisture reaches appropriate levels – typically 15-18% for small square bales and slightly lower for large round or square bales. Invest in moisture meters to accurately assess conditions rather than relying solely on visual or tactile assessments that can be misleading. Consider weather forecasts when planning harvest, avoiding cutting when rain is imminent within the drying window. Bacterial inoculants and proprietary preservatives offer additional options for managing slightly higher moisture levels when weather conditions force earlier baling, though these add cost and aren’t substitutes for proper drying. Maintaining appropriate moisture levels throughout storage prevents both mold development and dangerous heat buildup that can lead to spontaneous combustion.

Proper Stacking Techniques for Different Bale Types

Different bale formats require specific stacking approaches to maximize stability and minimize deterioration during storage. Small square bales benefit from interlocking patterns where each layer’s orientation alternates perpendicular to the previous, creating structural integrity that resists toppling. Large square bales should maintain tight, even stacks with minimal gaps, often benefiting from stacking equipment that ensures precise alignment. Round bales present unique challenges, ideally stored on end where the twine or net wrap provides maximum protection against moisture penetration, rather than on their curved sides where water can pool. When stacking round bales, pyramid configurations with maximum three bales high provide stability while allowing some airflow between units. Regardless of bale type, ensure adequate space between stacks for air circulation and equipment access during retrieval.

Temperature Monitoring and Fire Prevention

Newly stored hay requires vigilant temperature monitoring, as microbial activity in too-moist hay can generate dangerous heat levels. Temperatures between 150-175°F (65-80°C) indicate critical conditions that can progress to spontaneous combustion, necessitating immediate action including possible removal of affected bales. Digital temperature probes designed specifically for hay monitoring offer the most reliable measurements, allowing detection of internal heating that might not be apparent from external observation. Establish a regular monitoring schedule, with more frequent checks during the first three weeks after storage when risk is highest. Maintain fire prevention measures including proper electrical system maintenance, equipment heat shields, no-smoking policies, and clear access routes for emergency equipment. Strategic stack spacing creates beneficial firebreaks that can prevent total loss should a fire occur despite preventive efforts.

Pest Management in Hay Storage

Stored hay attracts numerous pests that can damage feed quality and create health hazards for both humans and livestock. Rodents represent a primary concern, not only consuming and contaminating hay but also creating fire hazards through nesting behaviors that can ignite from friction or chewed electrical wires. Implement integrated pest management approaches including physical barriers, proper sanitation practices, and strategic trap placement rather than relying solely on rodenticides that may pose secondary poisoning risks to livestock or pets. Birds introduce additional contamination concerns through droppings, with netting or enclosed structures offering effective deterrence. Insects such as weevils or mites typically indicate moisture problems requiring correction of underlying storage conditions rather than chemical treatments. Regular inspection helps identify pest activity before it becomes widespread, allowing targeted interventions that preserve feed quality.

First-In, First-Out Inventory Management

Implementing a disciplined first-in, first-out (FIFO) feeding system ensures hay rotates properly through your storage, preventing situations where older bales deteriorate while newer hay gets fed. Practical FIFO implementation requires intentional stack arrangement that facilitates access to oldest hay first, sometimes necessitating separate storage areas for different cutting dates. Clear labeling systems using weatherproof tags or colored twine help identify harvest dates and quality grades when visual distinction isn’t obvious. Consider creating detailed inventory maps for larger operations, documenting stack positions, quantities, and quality assessments to optimize feeding decisions. Consistent FIFO practices maximize nutritional delivery while minimizing waste from deteriorated older hay that livestock might refuse.

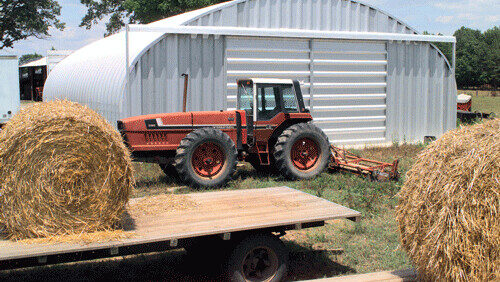

Equipment Considerations for Hay Handling

Proper equipment selection dramatically impacts storage efficiency and hay preservation outcomes. Front-end loaders with specialized hay attachments, including spears, grapples, or squeeze attachments, allow precise placement without damaging bale integrity. Dedicated hay trailers with proper weight ratings and security features prevent dangerous load shifts during transport between field and storage. Automated stacking systems represent significant investments that larger operations often find economically justified through labor savings and improved stack quality. Even basic tools like properly sized tarps, UV-resistant twine for repairs, and appropriate safety gear contribute to successful storage outcomes. Ensure all equipment operators receive proper training not only in mechanical operation but also in how their handling practices impact hay quality during the storage process.

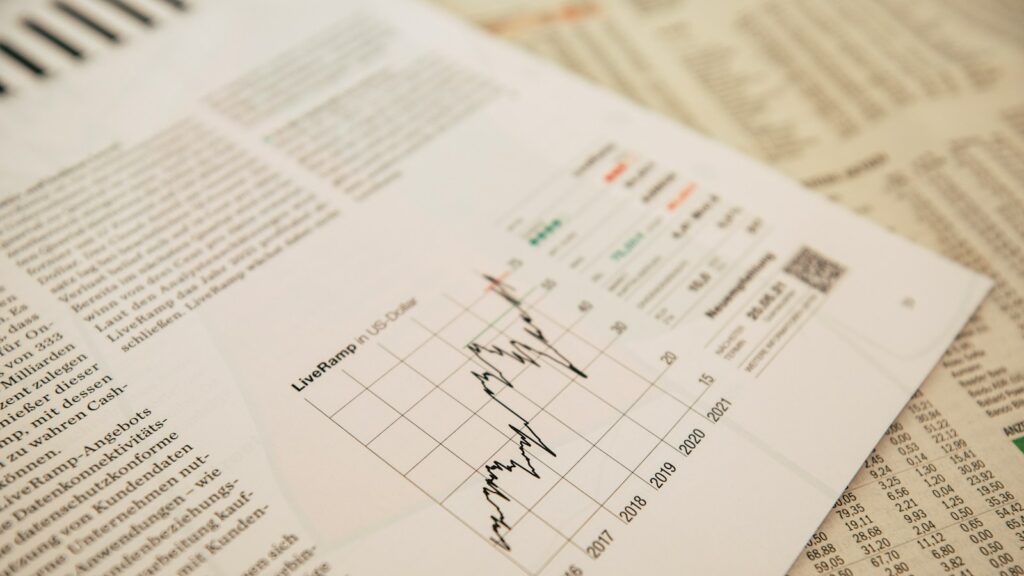

Economic Analysis of Storage Investments

Calculating the return on investment for hay storage improvements requires understanding both direct savings and indirect benefits. Direct calculations compare the percentage of hay typically lost to deterioration under current methods against projected losses with improved storage, multiplied by current market values and annual volume. Indirect benefits include labor savings from more efficient systems, reduced equipment wear from handling damaged bales, and improved animal health from consistent nutrition quality. Consider tax implications of different storage investments, as some agricultural structures qualify for accelerated depreciation or other beneficial treatment. Many producers find properly designed storage systems pay for themselves within 3-5 years through reduced waste alone, with continued returns throughout the structure’s usable life. Even incremental improvements like adding pallets under outdoor stacks often show positive returns within the first season.

Special Considerations for Organic and Premium Hay

Producers of certified organic or premium horse-quality hay face additional storage considerations to maintain certification status and premium market positioning. Organic certification requires maintaining a clear separation between organic and conventional hay to prevent cross-contamination, with documented handling protocols and comprehensive record-keeping systems. Premium horse hay markets demand not only nutritional preservation but also aesthetic qualities, including proper color retention and freedom from any mold or dust that could trigger respiratory issues in performance animals. These markets justify additional storage investments, such as climate-controlled facilities that preserve both feeding value and marketable appearance. Consider the certification requirements and buyer expectations specific to your target market when designing storage systems, as premium markets often compensate for additional storage costs through higher sale prices.

Seasonal Adaptations for Year-Round Quality

Successful hay storage requires adapting practices to seasonal challenges throughout the year. Summer storage focuses on heat management and moisture exclusion, often benefiting from additional ventilation and monitoring for spontaneous heating risks. Fall preparation involves ensuring waterproof integrity before winter precipitation begins, with inspection and repair of any covering systems and verification of drainage systems around storage areas. Winter storage management shifts focus to access considerations during snow and ice conditions, with planned pathways for equipment and potential emergency feed retrieval during severe weather. Spring brings renewed moisture challenges from increased humidity and ground water, requiring vigilance against condensation and timely transition to any new storage areas before the first cutting. These seasonal adaptations maintain continuous protection regardless of changing environmental conditions.

Technology Innovations in Hay Preservation

Emerging technologies offer new approaches to traditional hay storage challenges, with several innovations gaining traction among forward-thinking producers. Remote monitoring systems using wireless sensors now allow continuous temperature and moisture tracking with smartphone alerts when conditions exceed preset parameters. Advanced wrapping systems utilizing oxygen-limiting films create near-anaerobic conditions that preserve high moisture forages with minimal fermentation losses. Computer modeling tools help optimize stack configurations and airflow patterns when designing new storage facilities, maximizing capacity while maintaining proper ventilation. Drone-equipped infrared cameras can identify hot spots in large stacks before they reach combustion temperatures, allowing targeted intervention. While the initial investment in these technologies may seem substantial, their ability to prevent catastrophic losses often justifies the expense for larger operations where hay inventory represents a significant capital investment.

Conclusion

Effective hay storage represents a critical management practice that protects both financial investment and animal health throughout the changing seasons. By implementing appropriate storage methods tailored to your specific operation size, climate challenges, and market requirements, you can significantly reduce waste while ensuring consistent nutrition for your livestock. Whether you’re constructing dedicated facilities or maximizing outdoor storage effectiveness, the fundamental principles of moisture control, proper stacking, and diligent monitoring remain consistent. As feed costs continue to represent a significant portion of livestock production expenses, the return on investment for improved storage practices becomes increasingly apparent. With thoughtful implementation of these best practices, producers of all scales can maintain hay quality from harvest to feeding, regardless of the season or weather challenges.